|

|

|

|

| |

| |

| Resistance to roller deflection/bending |

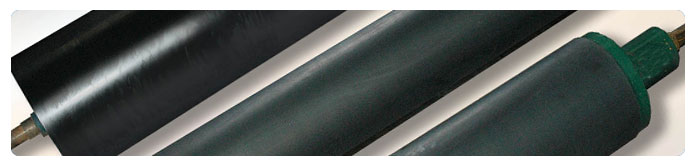

Carbon fibre reinforced roller cores offer a series of significant benefits compared to traditional materials such as steel and aluminium. The advantages of these mo-dern roller materials are increasingly being recognised and utilised both by engineers who design modern printing presses and the printers who run them.

Their excellent weight/material strength ratio makes carbon fibre rollers ideal for all applications demanding maximum strength at minimum mass/weight (greatly improved ease of handling, reduced energy con-sumption) or resistance to roller deflect-tion/bending, particularly on very broad presses.

As these materials are so new to printing press design, each potential application has to be thoroughly analysed with regard to the specific design objectives and application conditions in order to ensure that the carbon fibre rollers are in fact equipped to solve the problems their use is expected to eliminate or alleviate. To a much greater extent than steel or other metallic materials, carbon fibre construc-tions offer the engineer the ability to create an „inner structure“, depending largely on the choice of fibre type and the winding pattern, but also on the mechanical and chemical properties of the matrix sur-rounding the fibres and making up the body of the construction. In this way, a roller can be optimised with regard to weight, stiffness, thermic stability or cost. |

| |

| Various sets of properties |

Böttcher has been producing and covering carbon fibre rollers for a whole variety of applications for many years. In the graphic arts industry, we supply carbon fibre rollers not only for sheet-fed and web offset presses, but also for flexo and gravure applications. Our experience in this area, in combination with special Böttcher-develop-ed software for calculating the physical properties of various roller constructions (e.g. deflection/bending), gives us the expertise necessary to design and build the optimum roller for your specific requirements.

The choice of fibre type, the winding specifications (number of layers, winding angle of each layer, etc.) and the charac-teristics of the surrounding matrix work together to produce different sets of properties which affect not only the roller’s behaviour in the application context itself, but also its ability to be recovered (in the case of rubber-coated or other covered rollers) a certain number of times, thereby decisively influencing its productive life. When determining the materials for com-plementary components, such as journals, it is important to ensure the compatibility of the different materials under the anti-cipated conditions of use (e. g. their co-efficient of thermal expansion, particularly when the roller will be subjected to a vulcanisation process). The experience and know-how of the Böttcher group in all these areas ensures that your investment in carbon fibre rollers will not be wasted, but will give you the results you are looking for. |

| |

|

|

|