|

|

|

|

| Compound |

Hardness Shore A |

| 311 |

35 |

| 111 |

25 |

| 211 |

30 |

| 411 |

40 |

| 511 |

45 |

|

| |

| |

|

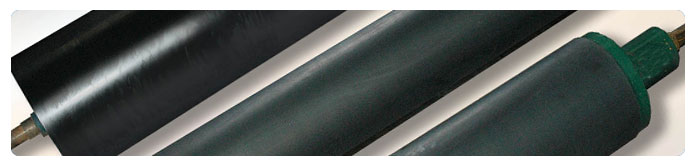

Ink form roller |

|

Distributor roller |

|

Vibrator roller |

|

Ink/form dampening roller |

|

|

| |

Application |

| |

|

|

| |

|

Best dynamic properties for high speed applications |

|

Very good chemical resistance to shrink inducing heatset inks |

|

Resistant also to coldset inks |

|

Very good geometrical and hardness stabilities |

|

Features |

|

| |

|

| |

|

Complimentary resistance test is recommended |

|

OEM compound for: Goss, Koenig & Bauer, MAN Roland and Wifag |

|

Note |

| |

|

|

| |

|

|

Sets new benchmarks regarding

Heat build-up in the printing unit

Shrink resistance of roller coverings |

|

Less ink misting due to reduced heat build-up of printing rollers and inks |

|

Reduced forces in the roller nip and reduced heat build-up contribute to an energy optimised print process |

|

Very high service life |

|

Reduced expenditure for roller setting, even print stripe |

|

High dynamic load-bearing capacity |

|

More constant print conditions |

|

Benefits |

|

|

|