|

|

|

|

| |

| Web Offset |

| Ink Spaying in Film Inking Units … |

For inking units in offset presses equipped with film rollers, the ink transfer is assured continuously from the ink duct across the ink ductor to the adjacent film roller. A rubber covered transfer roller, in a 20 to 80 Shore A hardness range, is set to the film roller to regulate the ink transport to the inking unit’s roller system.

In the area of the ink feed, the printing ink has a higher thickness than in the further course of the inking unit. Often, this leads to undesired ink spraying between the film roller and the distributor roller, particularly in the nips running out. The consequences are heavy soiling of the press and higher cleaning expenditure. |

| |

| … can be avoided! |

| The SprayLo ink distributor roller, a combined development between Böttcher and KBA, has a special roller surface structure which increases the transfer efficiency between the film roller and the first ink distributor roller. This allows the printer to reduce the ink thickness on the film roller, which avoids disturbing ink spraying on this position to a large extent. |

|

| |

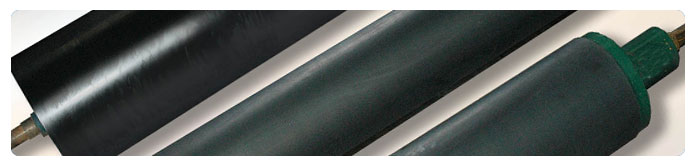

| Product Description |

The uniform surface structure of the SprayLo roller shows an averaged rough-ness value of 40 to 60 μm Rz (smooth offset rollers have < 10 μm).

Ideally suited as core materials are steel, aluminium, CFR and GFR plastics. |

| |

| Use |

| The SprayLo ink distributor roller can be used in KBA web offset presses with film inking systems, in combination with a conventional film roller or in combination with the special laser engraved film roller from Böttcher. |

|

|