|

|

|

|

| |

| Web Offset Printing |

| General |

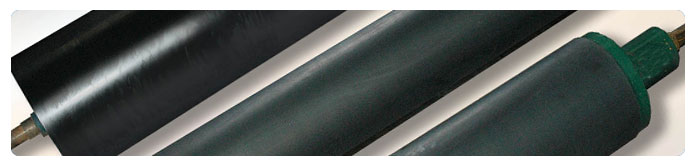

Rilsan covered film rollers have been part of the Böttcher product range for years. Depending on the press type, these rollers are manufactured with cross or spiral groove profiles. The advantages adjudi-cated to the material are well-known:

| |

|

|

Good and regular ink transfer |

|

Wear resistance, long service life |

|

Swell resistance against inks and printing che-micals. |

Despite the acknowledged merits of these con-ventionally manufactured film rollers compared to traditional copper plated rollers, printers com-plain about abrasion problems and wear-out of the adjacent rubber covered distributor roller. And very often printers have to draw on special cleaners in order to get a satisfactory cleaning result and to remove all dried ink out of grooves and furrows. |

| |

| An Innovative Roller Surface |

In terms of surface processing Böttcher is entering unknown territory with the stochastically la-ser engraved surface structure. Based on complex probability calculations a special computer programme modulates the laser frequency to that effect that successively a special structure which is not permanently repeating - thus more or less irregular - is built up on the roller surface.

The result is a congenially smooth, rounded surface without any sharp edges or spurs which guarantees an optimal ink transfer. |

|

| |

| The advantages are considerable: |

| |

|

|

better colour control and better ink transfer due to controlled (reduced) ink film thickness |

|

extended service life of the rubber covered distributor roller (reduced abrasion, less tear and wear) |

|

ink transfer free of stripes, steady impression |

|

the roller surface can be custom made accord-ing to the requirements of the printing press and other individual prerequisites. |

|

| |

| You want to know more? Don’t hesitate to con-tact us; our engineers are gladly at your service for technical advice. |

|

|