|

|

|

|

| |

| |

| |

Blanket for heatset webs (up to 48 pages) and sheet-fed presses (paper and carton)

For the highest mechanical and chemical demands in the pressroom |

| |

| |

| Application |

| |

|

Presses: |

Web Heatset |

|

Packing height: |

In most cases, 0.02/ 0.03mm less than OEM recommendations |

|

Substrates: |

Paper (coated, uncoated, LWC) |

|

Lnks: |

conventional and vegetable oil-based, hybrid/UV (conditional) |

|

Wash-up solvents: |

conventional and vegetable oil-based,

hybrid/UV (conditional) |

| |

|

|

|

|

| |

Application |

| |

|

|

| |

| Features |

|

| |

|

|

Micro-ground and polished printing surface, controlled roughness 0.9 – 1.2 μm |

|

Hydrophilic surface compound especially developed for alcohol reduced (<5%) and alcohol free printing |

|

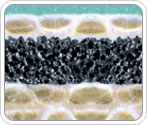

High compressibility resulting from 3-ply construction and high content of closed cells |

|

Pressurised compressible layer |

|

Features |

|

| |

|

| |

| Physical Properties |

| |

|

Overall hardness: |

79° Shore A |

|

Tensile strength: |

> 3,750 N/50 mm |

|

Elongation at 500N/50 mm: |

< 2 % |

|

Gauge loss at tensioning and running: |

< 2 % |

|

Indentation at 100N/cm²: |

0.14 mm (7.1 %) |

|

Indentation at 200N/cm²: |

0.23 mm (11.7 %) |

|

Physical Properties |

| |

|

|

| |

|

| Benefits |

|

| |

|

|

Well balanced halftone and solid quality |

|

Excellent ink release for minimum ink build-up and/or ink back-trapping from previous units |

|

Excellent resistance to excess-pressure (wrap-arounds, web changes, edge cuts, etc.) |

|

Low energy loss in the time, extended service life |

|

Benefits |

| |

|

|

| |

|

| Construction |

| |

|

Fabrics: |

3 |

|

Compressible layer: |

Closed cells, pressurised |

|

Identification lines: |

2 x blue |

| Surface |

|

Colour: |

Green |

|

Finish: |

Ground and polished |

|

Roughness (Ra): |

0.9 – 1.2 μm |

|

Micro hardness: |

63° Shore A |

| Gauge |

|

Nominal gauge: |

1.96 mm (+/- 0.02 mm) |

|

Gauge uniformity per blanket of max. 1 m²: |

+/-0.015 mm |

|

Construction |

|

|

|